X-Ray Inspection System for Large Fish Bone

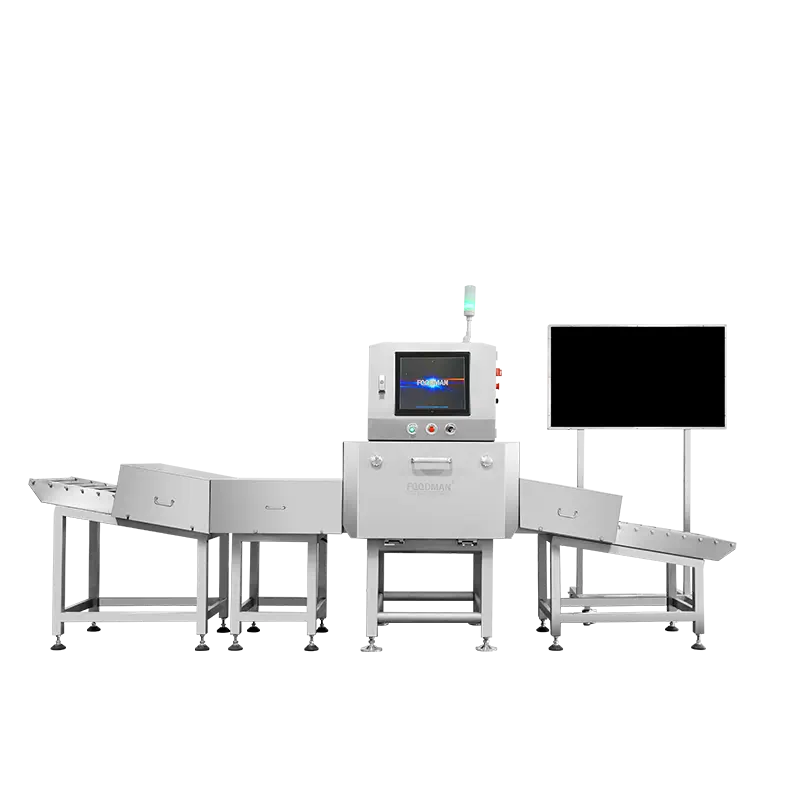

Detect foreign objects in fish meat and fish bones left during fish processing. An external HD display screen is convenient for manual inspection.

The Foodman X-Ray Inspection System for Fishbone is specifically designed to detect small fishbones in fish meat with high precision, making it an invaluable tool for fish processors focused on enhancing product safety and quality.

This system is versatile and adaptable for a wide range of products, including fillets, whole fish, and processed fish items, making it ideal for different production environments. Its flexibility increases efficiency while maintaining the highest safety standards.

With ultra-high-resolution imaging and TDI (Time Delay Integration) technology, the system captures highly detailed images, enabling precise identification of fishbones, even those that are usually hard to detect. Powered by Foodman’s proprietary FIAP (Foodman Intelligent Algorithm Platform), the Foodman X-Ray Inspection System further enhances detection accuracy, ensuring that no fishbone is overlooked.

APPLICATIONS

tunny

salmon

cod

sardine

TECH SPECS

Model: FXR-YC Series

X-ray source: 80kv,350w

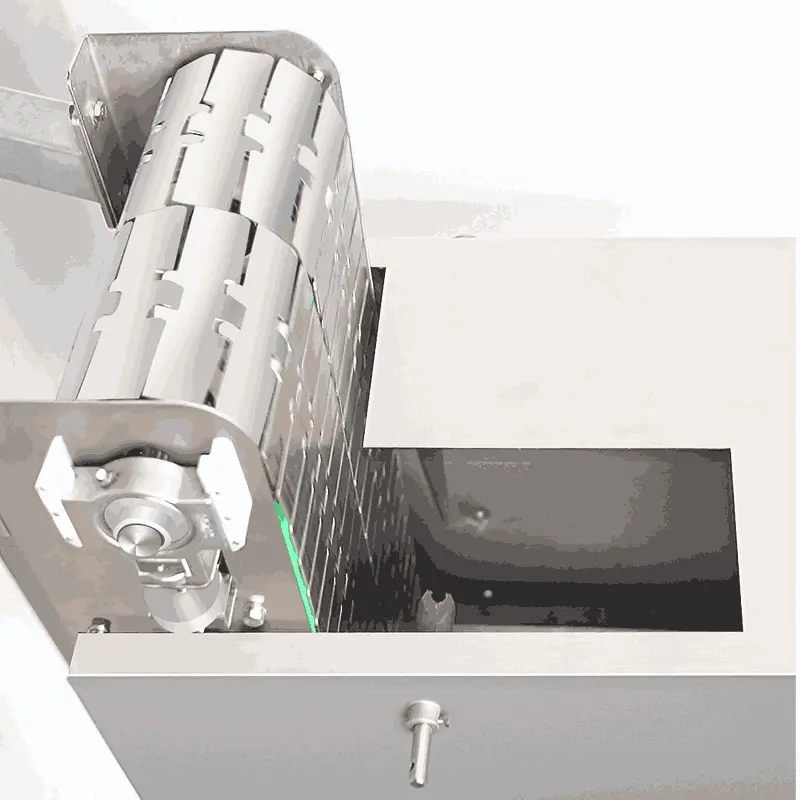

Detector: 0.1mm TDI detector

Channel width: Maximum width 300mm

Channel height: Maximum height 170mm

Conveyor belt speed:5-30 m/min

Weight/size of the product to be detected:Maximum 10kg

Sensitivity(mm):

Fishbone 0.1mm

Stainless steel ball 0.2mm

Stainless steel wire 0.1mm*2

Ceramic, glass balls 0.8mm

Operation instructions: Windows system, 50-inch HD external screen, 17-inch color touch screen

Support data: interface LAN Port ,USB port

Protection:Protection cabin

Power supply: Single phase AC220V/110V, 50-60Hz

Rejection metho: SUS304 stainless steel

Working environment:Temperature -10℃~40℃, humidity 30~90%

Waterproof: level Conveyor is IP66, other parts are IP54

Equipment material: SUS304 stainless steel

Light source leakage:< 1uSv/h

KEY FEATURES

Specialized Fish Bone Detection

This system is optimized to detect even the smallest and most challenging fish bones, including small rib bones and calcified bones, ensuring that fish products are bone-free.

Hardware Upgrade

The system is enhanced with TDI dual-energy detectors, which improve detection accuracy by effectively distinguishing between different materials and densities. Additionally, it features a beryllium window light source, enabling higher sensitivity and clarity in imaging.

Adaptable Design

Suitable for detecting bones in different fish products, both raw and processed, ensuring the highest quality and safety standards.

AI-Driven Algorithms

Incorporates FIAP image processing technology with AI algorithms for real-time, precise identification of fish bones in various types of fish. Automatically adjusts detection parameters based on real-time data to refine detection models and enhance performance without manual intervention.

Easy Operating Interface

Foodman utilizes the latest Windows operating system, featuring a 50-inch 4K ultra-clear display and a 17-inch full-color touch screen for enhanced image clarity. With a streamlined and intuitive interface, it ensures ease of use, prevents data loss, and includes a built-in backup function for added security.

Using FLAP Technology

The Foodman X-Ray Inspection System utilizes FIAP image processing technology, elevating detection precision to new standards, ensuring a thorough and reliable inspection process and enhancing product safety and quality across every scan.

What Makes FOODMAN X-RAY INSPECTION SYSTEM DIFFERENT?

AI Based Technology