In today‘ s fast-paced production environments, maintaining high standards of quality control is essential to meet consumer expectations and industry regulations. One critical aspect of quality control is ensuring the integrity of labels and seals on products. The Foodman Vision Inspection System for Label & Sealing, specifically the FVI-LS360 Series, offers a comprehensive, automated solution to improve quality control and efficiency across various industries.

Introduction: The Importance of Label & Sealing

The Critical Role of Label and Seal Quality

Label and seal quality plays a crucial role in protecting brand reputation and building consumer trust. Clear, accurate labels provide essential product information such as nutritional facts, ingredient lists, and expiration dates. Incorrect or poorly applied labels can lead to consumer confusion, potential health risks, and a loss of trust in the brand.

Seals are just as important, ensuring product freshness, preventing contamination, and confirming authenticity. A compromised seal can lead to leaks, spoilage, and even contamination. Furthermore, many industries are required to comply with strict regulations regarding labeling and sealing, and non-compliance can result in costly recalls, waste, and damage to brand reputation.

Challenges in Traditional Inspection Methods

Traditional label and seal inspection methods often involve manual checks, which are prone to human errors and inconsistencies. High-speed production lines increase the likelihood of undetected defects, resulting in the shipment of subpar products to consumers. These challenges highlight the need for automated, AI-driven solutions that offer precision and efficiency.

Introducing the Foodman Vision Inspection System (FVI-LS360 Series)

The Foodman Vision Inspection System (FVI-LS360 Series) is designed to tackle the challenges faced by manual inspection methods by providing a high-performance solution for label and seal inspection. With its progressive technology, the system enhances quality control processes by ensuring that labels and seals meet industry standards with unparalleled accuracy.

Overview of the FVI-LS360 System

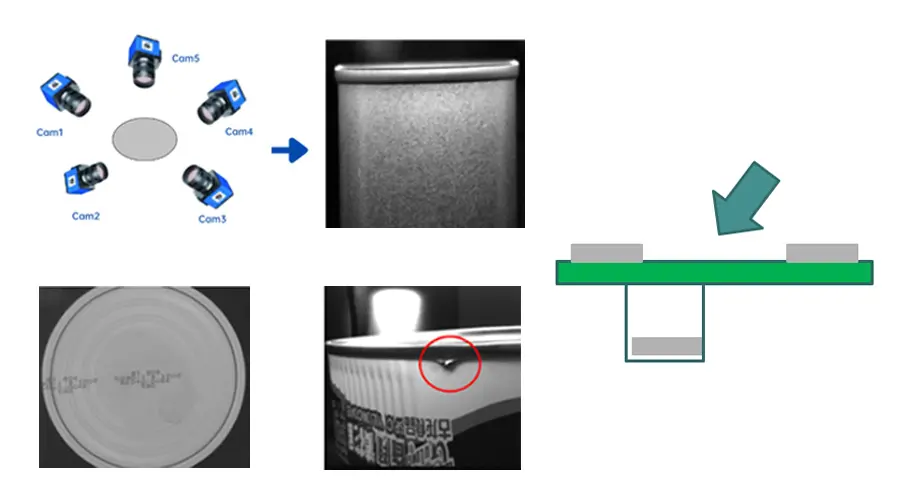

The FVI-LS360 features 360° full-range vision inspection for comprehensive defect detection. It leverages high-speed, AI-powered analysis to provide real-time quality control, making it an indispensable tool for any production line. The system seamlessly integrates with existing production environments, allowing manufacturers to upgrade their quality inspection processes without disrupting their operations.

Key Components of the Vision Inspection System

Image Acquisition: The system uses multi-angle cameras to capture high-resolution images of each product.

Data Processing: AI algorithms analyze these images to detect a wide range of defects, ensuring precision in quality control.

Execution Unit: The system either automatically removes defective products from the production line or sends real-time alerts for further investigation.

Advanced Features of the FVI-LS360 Series

Label Accuracy & Coding Inspection

One of the most crucial functions of the vision inspection system is label inspection. The FVI-LS360 accurately detects missing, misaligned, or incorrect labels on packaging. It also verifies barcodes, QR codes, and batch numbers to ensure they comply with industry standards. The system guarantees that all printed information, such as product names, expiry dates, and batch numbers, are legible and correctly positioned on the label.

Seal Integrity Inspection

The seal inspection system built into the FVI-LS360 is designed to identify improper sealing that could lead to leaks or contamination. The system evaluates seal flatness and alignment to ensure optimal protection for the product’s shelf life. It also checks for tamper-proof features, safeguarding consumers from potential safety risks associated with packaging breaches.

Structural Damage Detection

Beyond label and seal inspection, the system excels in detecting structural damage such as scratches, dents, or cracks in the packaging. Whether it‘s aluminum cans, plastic bottles, or blister packs, the FVI-LS360 can identify deformations that could compromise the product‘ s appeal and integrity.

Progressive Technology Behind Foodman Vision Inspection

AI-Powered Deep Learning Algorithm (FDM VISION)

The vision systems for inspection are powered by advanced AI algorithms that are trained to recognize defects with remarkable accuracy. The system learns from just 1,000 sample images to establish a detection model. Over time, the system continuously improves, refining its accuracy and reducing false positives. This ensures that every product is inspected to the highest standard without the need for manual intervention.

High-Speed Image Processing & Real-Time Analysis

The vision systems for quality inspection provide real-time analysis, allowing for instant identification of defects without slowing down the production line. The system automatically rejects defective products, ensuring that only top-quality products are shipped to consumers. Additionally, it can adapt to various product shapes and materials, making it highly versatile.

Smart Integration & Automation Features

The FVI-LS360 is customizable for different production environments, allowing manufacturers to tailor the system to their specific needs. Its user-friendly HMI interface ensures that operators can easily monitor the system in real time. The system also includes remote diagnostics and predictive maintenance features, minimizing downtime and ensuring that production runs smoothly.

Industry Applications: Ensuring Quality Across Sectors

Food & Beverage Industry

In the food and beverage industry, label verification is crucial for displaying accurate nutrition facts, batch details, and branding information. The label inspection system also ensures that packaging is free from damage, while seal integrity checks prevent contamination in cans, sauces, and packaged meals.

Pharmaceutical Industry

For pharmaceutical companies, the FVI-LS360 performs rigorous seal inspection and verifies barcodes for batch tracking and regulatory compliance. The system detects any perforations, leaks, or deformations in packaging, ensuring the safe delivery of products.

Cosmetics & Personal Care Industry

In the cosmetics and personal care industry, the vision inspection system guarantees smooth, damage-free packaging for premium products. It checks for seal integrity in tubes, pouches, and bottles, and verifies label alignment to maintain brand consistency.

Why Choose the Foodman FVI-LS360 Series?

Key Benefits of the System

- 360° comprehensive inspection for complete defect detection

- AI deep learning technology for high-speed, high-accuracy results

- Real-time monitoring and traceability for improved quality control

- User-friendly interface and remote diagnostics for easy maintenance

Competitive Advantage Over Traditional Systems

Compared to traditional manual inspection methods, the FVI-LS360 provides faster defect detection, reducing the risk of product recalls and waste. The system‘s adaptability to multiple industries and customizable configurations give it a competitive edge in the marketplace.

Conclusion: Elevate Your Quality Control with Foodman Vision Inspection

The FVI-LS360 Series sets a new industry standard for vision inspection systems. With its advanced AI-powered technology, real-time analysis, and customizable features, it provides manufacturers with the tools they need to maintain impeccable quality control across diverse industries. As the future of quality assurance continues to evolve, AI-powered automation will play an increasingly vital role in ensuring product integrity.