Ensuring Food Safety: The Role of X-Ray Inspection in Detecting Bone Fragments in Meat and Seafood

Importance of Food Safety in the Meat and Seafood Industry

Food safety is a critical concern in the meat and seafood industry, where contamination risks can lead to severe health hazards, regulatory penalties, and brand damage. Ensuring that products are free from harmful contaminants like bone fragments, metal, and other foreign objects is essential for maintaining consumer trust and compliance with food safety standards.

Traditional inspection methods, such as manual checks and metal detectors, often fall short in detecting non-metallic contaminants. This is where X-Ray inspection plays a vital role. Advanced X-Ray inspection systems provide high-precision detection, identifying even the smallest bone fragments in processed meat and seafood. By integrating X-Ray inspection technology, manufacturers can enhance safety, reduce recalls, and ensure their products meet industry regulations.

Investing in X-Ray inspection not only improves food safety but also strengthens brand reputation, ensuring that consumers receive high-quality, contaminant-free meat and seafood products.

Risks Associated with Bone Fragments in Processed Meat and Seafood

Bone fragments in processed products pose choking hazards and can cause injuries to consumers. Traditional inspection methods, such as manual checks and metal detectors, often fail to identify small or non-metallic fragments. This makes advanced food X-Ray inspection equipment a necessary solution for meat safety and seafood safety.

How X-Ray Inspection Enhances Detection Accuracy and Product Quality

Modern food X-Ray inspection technology provides superior detection capabilities compared to conventional methods. Food X-Ray machines can identify even the smallest bone fragments, improving safety without compromising production efficiency. By integrating food X-Ray inspection systems, manufacturers can enhance food quality, comply with food industry regulations, and build consumer confidence. Investing in food X-Ray machines ensures that meat and seafood products meet the highest safety standards, protecting both consumers and brands.

The Challenges of Detecting Bone Fragments

Ensuring meat safety and seafood safety requires effective detection of bone fragments, which can pose risks to consumers and damage a brand’s reputation. However, identifying these contaminants comes with several challenges.

Variability in Bone Size, Shape, and Density

Bone fragments in meat and seafood vary significantly in size, shape, and density, making detection difficult. Small, thin, or soft bones may not be easily visible through traditional screening methods, increasing the risk of contamination reaching consumers.

Limitations of Traditional Detection Methods

Traditional methods, such as manual inspection and metal detectors, often fail to detect bone fragments effectively. Manual checks are time-consuming and prone to human error, while metal detectors cannot identify non-metallic contaminants like bones, plastic, or glass. This gap in detection highlights the need for advanced food X-Ray inspection technology.

Impact of Undetected Bone Fragments

If bone fragments go undetected, they can lead to serious consumer health risks, including choking hazards and injuries. Additionally, failing to comply with food industry regulations can result in product recalls, legal consequences, and damage to brand reputation.

To overcome these challenges, manufacturers are turning to food X-Ray inspection equipment. High-precision food X-Ray machines provide superior detection of bone fragments in various meat and seafood products, ensuring enhanced food quality and regulatory compliance. By investing in X-Ray inspection, businesses can safeguard their consumers and maintain trust in their brand.

How X-Ray Inspection Works for Bone Fragment Detection

Ensuring meat safety and seafood safety requires advanced detection methods to identify bone fragments that could compromise food quality. Food X-Ray inspection technology has become the preferred solution for detecting even the smallest bone fragments in meat, poultry, and seafood. Here’s how it works.

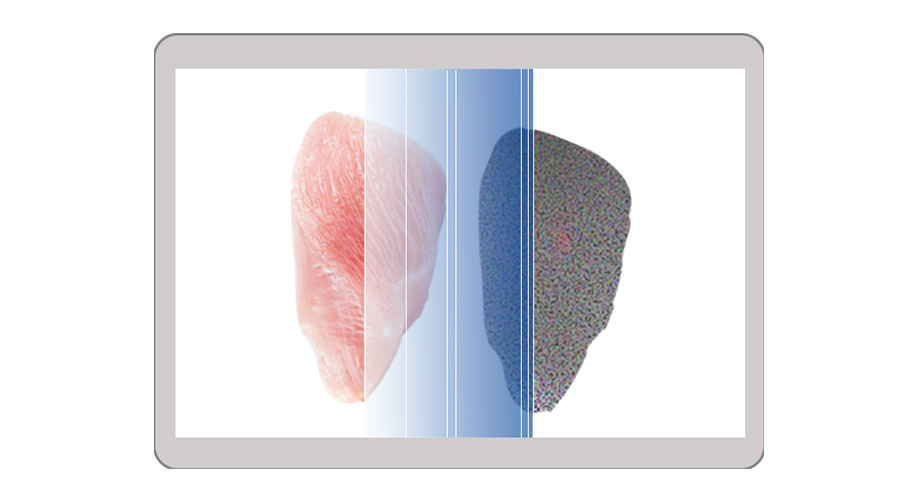

Principle of X-Ray Penetration and Density Differentiation

X-Ray inspection machines work by transmitting X-Rays through food products. Since bones have a different density than meat or seafood, the system can distinguish them based on how much radiation they absorb. This makes it possible to detect bones that traditional methods, like metal detectors, would miss.

Advanced Image Processing for Detecting Low-Density Bones

Modern food X-Ray inspection equipment uses AI-powered image processing to identify even low-density bones, such as fish bones or poultry bones. By analyzing variations in X-Ray absorption, the system enhances visibility of contaminants, improving detection accuracy.

Real-Time Analysis and Automated Rejection of Contaminated Products

Once a food X-Ray machine identifies bone fragments, it immediately signals an automated rejection system to remove the contaminated product from the production line. This ensures compliance with food industry regulations while minimizing the risk of unsafe products reaching consumers.

By integrating X-Ray inspection into food processing, manufacturers enhance food quality, protect consumers, and maintain compliance with industry standards, ensuring the highest level of safety in meat and seafood production.

Advantages of X-Ray Inspection in Meat & Seafood Processing

In the food processing industry, ensuring meat safety and seafood safety is paramount to maintaining high food quality. X-Ray inspection has become a powerful tool to help detect bone fragments and other contaminants, offering several advantages over traditional methods.

High Accuracy in Detecting Small, Low-Density Bones

One of the key advantages of food X-Ray inspection is its ability to detect small, low-density bones, such as fish pin bones or poultry cartilage. Traditional metal detectors often fail to identify these smaller contaminants, but X-Ray inspection machines excel in spotting them due to their ability to differentiate materials based on density.

Non-Destructive Testing That Preserves Product Integrity

Unlike traditional methods like manual inspection or cutting open packages, X-Ray inspection equipment offers non-destructive testing. This means products can be examined for bone fragments or contamination without damaging the packaging or compromising the product’s quality. It ensures the food remains intact and ready for consumption.

Works with Various Packaging Types (vacuum-sealed, frozen, bulk products)

Food X-Ray inspection systems are versatile and can work with a wide range of packaging types, including vacuum-sealed, frozen, and bulk products. This flexibility makes them ideal for various meat and seafood products, ensuring that no matter the packaging, all items are thoroughly checked for safety.

Reduces Reliance on Manual Inspection, Improving Efficiency and Consistency

Manual inspection is time-consuming and prone to human error, but food X-Ray machines automate the process, greatly improving efficiency and consistency. By reducing reliance on human inspectors, companies can enhance their production lines, ensuring that every product is thoroughly inspected without delays.

X-Ray inspection is a game-changer for meat safety and seafood safety, helping manufacturers comply with food industry regulations while improving food quality and production efficiency.

Meeting Food Safety Standards & Industry Regulations

Ensuring meat safety and seafood safety is critical in today’s food industry. With increasing demands for high food quality and adherence to food safety standards, manufacturers must implement advanced technologies to meet strict regulations. X-Ray inspection plays a vital role in achieving compliance with industry standards and enhancing product safety.

Compliance with HACCP, FDA, USDA, and International Food Safety Regulations

Food X-Ray inspection systems are integral to complying with essential food industry regulations like HACCP, FDA, USDA, and international food safety standards. These regulations require manufacturers to demonstrate their commitment to eliminating contaminants, ensuring that every food product is safe for consumption. Food X-Ray machines are certified tools that help detect bone fragments, foreign objects, and other potential hazards, ensuring compliance with these regulations.

Minimizing Product Recalls and Liability Risks

Product recalls due to contamination pose significant risks to both consumer safety and a company’s reputation. With food X-Ray inspection equipment, manufacturers can detect contamination early in the production process, minimizing the chances of contaminated products reaching the market. By catching issues before they escalate, companies reduce their liability risks and avoid costly recalls, protecting both their brand and consumers.

Enhancing Consumer Confidence in Meat and Seafood Products

Consumers are becoming more conscious of the safety and quality of the products they purchase. The use of X-Ray inspection builds consumer confidence by ensuring that meat and seafood products are thoroughly checked for contaminants. Transparent food safety practices, supported by food X-Ray inspection, show that manufacturers are committed to providing safe, high-quality products, which in turn enhances trust and consumer loyalty.

X-Ray inspection is crucial for maintaining meat safety and seafood safety, ensuring compliance with critical food industry regulations while improving food quality and minimizing risks. It’s an investment that pays off by protecting both consumers and manufacturers alike.

Future Innovations in X-Ray Detection for the Food Industry

As food safety concerns continue to evolve, so do the technologies that help ensure the quality and safety of our products. X-Ray inspection plays a critical role in ensuring meat safety, seafood safety, and overall food quality. However, as consumer demands and regulatory requirements increase, future innovations in X-ray inspection are set to transform the food industry even further.

AI-Powered Detection for Improved Accuracy and Reduced False Rejects

One of the most exciting innovations in food X-Ray inspection is the integration of artificial intelligence (AI) into the detection process. AI-powered X-Ray machines can analyze images more efficiently and accurately than traditional systems, reducing the occurrence of false rejects. With AI’s ability to learn and adapt, X-Ray inspection equipment can offer precise identification of contaminants, such as bone fragments or foreign objects, without mistakenly rejecting good products. This ensures better quality control and higher yield, reducing waste and optimizing production efficiency.

Integration with Smart Manufacturing for Automated Quality Control

The future of food X-Ray inspection is closely tied to the rise of smart manufacturing. By integrating X-Ray inspection machines into fully automated production lines, manufacturers can ensure real-time, continuous quality control with minimal human intervention. This integration allows manufacturers to monitor and adjust production processes instantly, ensuring consistent meat safety, seafood safety, and compliance with food industry regulations. Automated systems powered by X-Ray inspection not only improve accuracy but also contribute to streamlined operations, reducing human error and maximizing productivity.

Continuous Improvements in Sensitivity for Detecting Even the Smallest Bone Fragments

As consumer expectations for product quality rise, manufacturers are focusing on developing X-Ray inspection systems with improved sensitivity. Innovations in X-Ray inspection technology will allow for the detection of even the smallest bone fragments in meat and seafood products, further ensuring safety and quality. These advancements will enable food X-Ray inspection equipment to detect low-density materials, such as fish bones or poultry cartilage, which were previously difficult to identify. By improving sensitivity, X-Ray machines for food inspection can better protect consumers from potential hazards and ensure adherence to stringent food industry regulations.

The future of X-Ray inspection in the food industry holds great promise. From AI-powered systems to greater sensitivity, these innovations will not only improve meat safety and seafood safety but also help manufacturers maintain food quality and meet the evolving demands of consumers and regulatory bodies.

Conclusion

The Necessity of X-Ray Inspection for Bone Fragment Detection in Meat and Seafood

In the meat and seafood industries, ensuring meat safety and seafood safety is critical to maintaining high food quality and meeting food industry regulations. X-Ray inspection plays a vital role in detecting bone fragments, which can pose significant risks to consumer safety. Whether it’s small fish bones or poultry cartilage, advanced food X-Ray inspection systems are capable of identifying contaminants that traditional methods, such as metal detectors or manual inspections, may miss. This technology provides a level of precision and reliability essential for ensuring the safety of food products.

How Food Processors Can Benefit from Investing in X-Ray Inspection Technology

For food processors, investing in X-Ray inspection machines is a proactive step toward enhancing product quality and safeguarding consumer trust. Food X-Ray inspection equipment not only helps detect bone fragments but also offers the ability to identify other contaminants, such as glass, plastic, or metal, while preserving the integrity of the product. By using X-Ray machines for food inspection, processors can meet regulatory requirements and reduce the risk of costly product recalls, all while improving operational efficiency. The non-destructive nature of X-Ray inspection ensures that food products remain unaltered during the inspection process, which is essential for maintaining food quality.

Encouraging Adoption of Advanced Detection Systems for Enhanced Food Safety

The importance of X-Ray inspection in food safety cannot be overstated. As consumer expectations for safe, high-quality food products continue to rise, adopting advanced detection systems, like food X-Ray inspection machines, becomes essential. By embracing X-Ray inspection technology, food processors can ensure compliance with safety regulations and provide consumers with confidence in the products they purchase. The continued innovation in X-Ray machines for food inspection promises even more precise and efficient detection capabilities, reinforcing food safety standards and driving the industry forward.