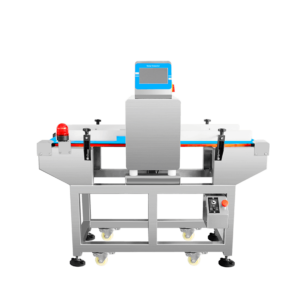

Combi Metal Detector and Checkweigher FMD-210

It is widely used in aquatic products, pickled products, vegetables, cosmetics, toy industries, etc. Save space and installation costs.

Experience the capabilities of our Combi Metal Detector and Checkweigher, the ideal solution for simultaneous metal detection and weight measurement. This versatile machine is perfect for a range of industries, including aquatic products, pickled items, vegetables, cosmetics, and toys.

In the food industry, it excels at detecting contaminants in various products such as meat, poultry, potatoes, tomatoes, seafood, nuts, and bread, ensuring both safety and quality.

Enjoy the convenience of a single machine that combines metal detection and weight checking, delivering efficient and reliable performance tailored to meet the needs of the food industry.

APPLICATIONS

bagged snacks

bagged frozen food

plastic bottled beverages

bottled cosmetics

TECH SPECS

Model: FMD(YCW)-210

Checking Range: ≤1000g

Weighing Accuracy: ±0.3g ~ ±1g

Minimum Scale: 0.1g

Belt Width: 210mm

Body Length: 1935mm

Working Speed: 30m/min

Power: AC220V±10% 50Hz(60Hz)

Sensitivity(mm)

FE: 0.8; NFE: 1.0; SUS304: 1.5

Operation: Touch screen and button

Power Supply: AC220/110V±10% 50Hz/60Hz

Rejector: Swing Arm/Pusher/Air Blast

Waterproof Level: IP54

Operating Requirement: Temperature: 0℃~40℃,Humidity:30%~95%

Main Structure: SUS304 Stainless Steel

KEY FEATURES

Dual Functionality

Combines advanced metal detection and precise weight measurement in one compact unit, optimizing production efficiency.

User-Friendly Interface

Designed for easy operation with intuitive controls, simplifying setup and minimizing training time for operators.

Data Logging Capabilities

Provides comprehensive data storage and reporting features, enabling users to track and analyze performance metrics for improved quality control.

Smart Learning Function

Our metal detector features an intelligent learning function that automatically configures product parameters, making operation simple and efficient.

Robust Construction

Built with high-quality materials to withstand demanding production environments while ensuring reliability and longevity.

Personalized Service

Our expert team is dedicated to delivering tailored solutions that meet your specific requirements and product dimensions. We also offer optional equipment components to suit your needs.

What Makes FOODMAN X-RAY INSPECTION SYSTEM DIFFERENT?

AI Based Technology