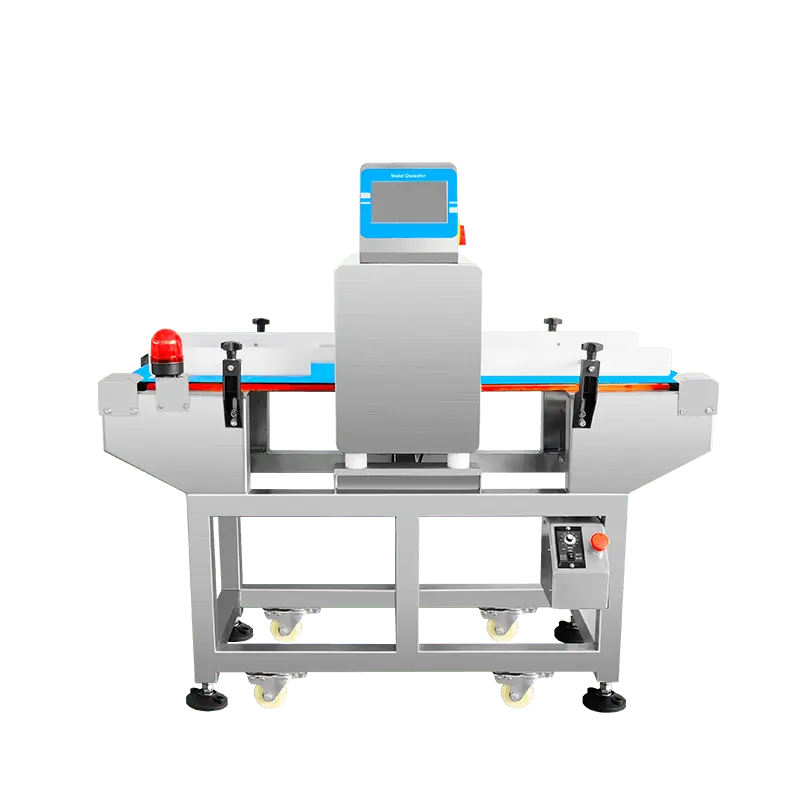

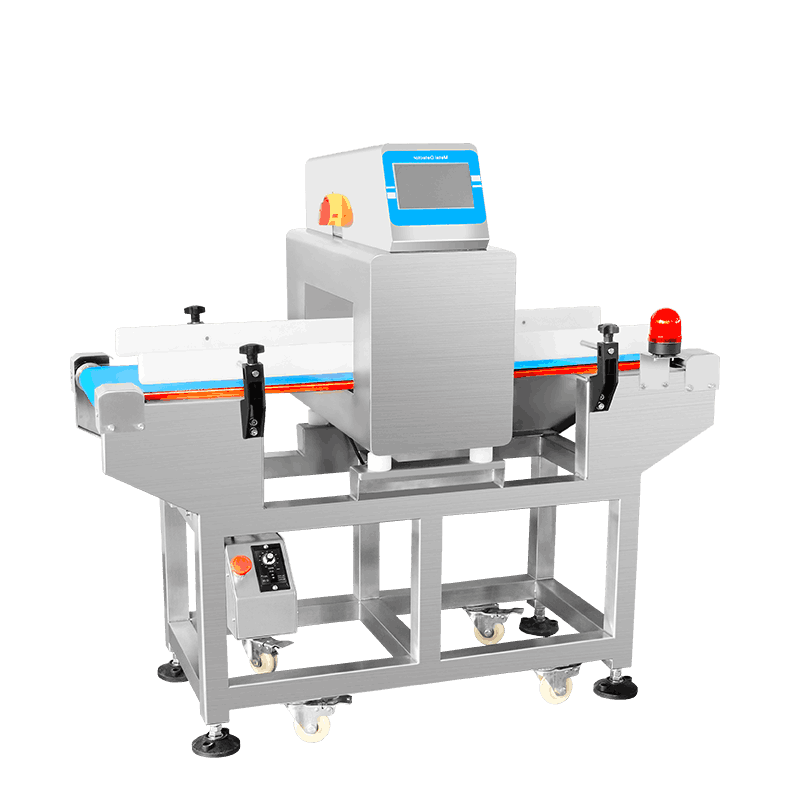

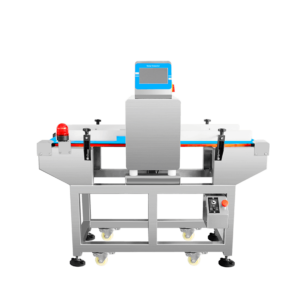

Conveyor Metal Detector FMD-3010

Metal foreign body detection for food processing, chemical materials, pharmaceuticals, cosmetics, toys, and other industries.

Ensure food safety with our Conveyor Metal Detector, expertly engineered to accurately identify metal contaminants such as ferrous, non-ferrous, and stainless steel during food processing.

This high-sensitivity and stable detector is perfect for a variety of industries, including food, poultry, chemicals, pharmaceuticals, cosmetics, and toys. It effectively handles a diverse array of packaged products, including bread, nuts, meat, poultry, sausages, and pills, guaranteeing reliable detection and maintaining quality standards.

Rely on our expertise to enhance product quality and compliance. Explore our complete range of conveyor metal detectors to protect your production line.

APPLICATIONS

bagged snacks

bagged frozen food

plastic bottled beverages

bottled cosmetics

TECH SPECS

Model:FMD-3010

Height(mm):100mm

Width(mm): 300

Body Length: 1500mm

Transmission Speed: 30m/min

Sensitivity(mm):FE: 0.8

NFE: 1.0

SUS304: 1.5;

Operation: Touch screen

Power Supply: AC220/110V±10% 50Hz/60Hz

Alarm: Audible and visual alarm

Rejector: Multi Rejector Selectable

Waterproof Level: High-Speed A/D Sampling Module

Product Preset: IP54/IP65

Operating Requirement: Temperature: 0℃~40℃,Humidity:30%~95%

Main Structure: SUS304 Stainless Steel

KEY FEATURES

Use DDS and DSP Technology

Our food metal detector features phase intelligent tracking along with DDS and DSP technology, delivering exceptional detection sensitivity and stability. Built with a hard-fill epoxy metal detector head, this system offers enhanced durability and consistent performance, making it ideal for rigorous food processing environments.

Automated Intelligent Learning

Our food metal detector features an intelligent learning function, automatically setting product parameters for streamlined operation. Experience easy and efficient configuration for optimal performance.

Powerful Storage Function

Equipped with Ferroelectric RAM, our food industry metal detector can store up to 100 different product parameters, offering flexibility and convenience for a wide range of applications.

Precision Metal Detection

Accurately identifies ferrous, non-ferrous, and stainless steel contaminants in food processing, ensuring enhanced food safety and quality.

High Sensitivity and Stability

Engineered for high-sensitivity detection with stable performance, minimizing false rejects and ensuring reliable operation in demanding environments.

Versatile Industry Applications

Ideal for a wide range of sectors, including food, poultry, chemical, pharmaceutical, cosmetics, and toy industries, providing flexible solutions for diverse processing needs.

What Makes FOODMAN X-RAY INSPECTION SYSTEM DIFFERENT?

Adaptability for Various Products