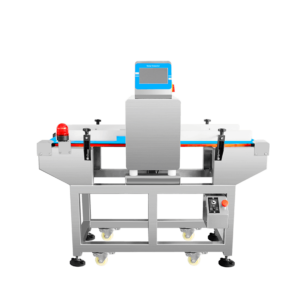

Free-Fall Metal Detector FMD-P-125

Perfect for detecting foreign metal objects in bulk materials such as powders and granules.

The Free-Fall Metal Detector is an essential tool for the agriculture and food processing sectors, meticulously designed to identify and remove metal contaminants such as iron, stainless steel, copper, aluminum, and metal wire from products. This device is critical for ensuring food safety and quality.

Engineered to inspect a wide variety of granular materials—including granules, milk powder, sugar, corn, tea, noodles, and crisps—this gravity fall metal detector offers high sensitivity, capable of detecting even the tiniest metal particles. Its sturdy construction guarantees durability and reliability in challenging industrial settings.

By investing in a Free-Fall Metal Detector, you not only protect your processing equipment from damage but also ensure compliance with industry standards. This enhances your quality control processes significantly, providing confidence in the safety and integrity of your products.

APPLICATIONS

bulk grain

bulk flour

bulk rice

bulk candy

TECH SPECS

Model:FMD-P-125

Accuracy Without Product:

Fe:φ0.7mm

Non-Fe:φ1.5mm

Sus304:Φ1.5mm

Detection Pipe Diameter:120mm

Throughput (L/h):10000

Separation Method: Automatic Separation

Operation: Touch Screen

Power Supply: AC220V、110V/50HZ

Pipe:PP and PTFE

Waterproof level: IP65

KEY FEATURES

Low Acoustic Emission

The Free-Fall Metal Detector operates at a sound level of under 63 dBA from one meter away, creating a quieter working environment. This low-noise feature minimizes workplace noise pollution and enhances overall comfort.

Robust Rejection Mechanism

Our detector efficiently eliminates various types of metal debris, including iron, non-magnetic stainless steel, and irregular metal wires, without the need for multiple settings. This ensures thorough removal of contaminants, optimizing safety.

Dynamic Temperature Range

The Free-Fall Metal Detector functions reliably across a wide temperature range of -10°C to 50°C and in humidity levels below 70% without condensation. This adaptability guarantees consistent performance in various conditions.

Adhere to International Regulations

Foodman’s Free-Fall Metal Detectors are meticulously designed to meet strict international food safety standards, fully complying with IFS, BRC, and FSMA guidelines. This alignment with global regulations guarantees robust food safety and consistent quality control throughout production.

Comprehensive Application

This detector is ideal for a diverse range of granular materials, including granules, milk powder, sugar, corn, tea, noodles, and crisps, making it well-suited for various food processing applications.

Sturdy Build

Designed to endure challenging industrial environments, this detector offers durability and longevity for continuous operation.

What Makes FOODMAN X-RAY INSPECTION SYSTEM DIFFERENT?

AI Based Technology