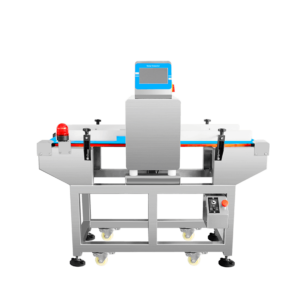

Free-Fall Metal Detector FMD-P-200

Ideal for identifying metal contaminants in bulk materials like powders and granules.

The Free-Fall Metal Detector is a critical tool for agriculture and food processing, expertly crafted to detect and remove metal contaminants—including iron, stainless steel, copper, aluminum, and metal wire—from products. This device is essential for maintaining high standards of food safety and quality.

Ideal for inspecting a wide variety of granular materials—such as milk powder, sugar, corn, tea, noodles, and crisps—this high-sensitivity metal detector can capture even the smallest metal particles. Built for durability, its robust design ensures reliable performance in challenging industrial settings.

By investing in a Free-Fall Metal Detector, you not only protect your processing equipment from potential harm but also meet stringent industry standards, enhancing quality control and reinforcing trust in the safety and quality of your products.

APPLICATIONS

bulk grain

bulk flour

bulk rice

bulk candy

TECH SPECS

Model:FMD-P-200

Accuracy Without Product:

Fe:φ0.8mm

Non-Fe:φ1.5mm

Sus304:Φ2.0mm

Detection Pipe Diameter:200mm

Throughput (L/h):14000

Separation Method: Automatic Separation

Operation: Touch Screen

Power Supply: AC220V、110V/50HZ

Pipe:PP and PTFE

Waterproof level: IP65

KEY FEATURES

Soft Sound Functionality

The Free-Fall Metal Detector maintains sound levels below 63 dBA at a one-meter distance, contributing to a quieter work environment. This low-noise design minimizes noise pollution, enhancing workplace comfort.

Powerful Rejection Feature

Our detector seamlessly removes a variety of metal contaminants—such as iron, non-magnetic stainless steel, and irregularly shaped metal fragments—without needing multiple adjustments. This ensures thorough contaminant elimination for optimal safety.

Customizable Temperature Range

With reliable performance across a temperature span of -10°C to 50°C and in humidity levels under 70% without condensation, the Free-Fall Metal Detector operates dependably in diverse conditions.

Conform to International Requirements

Foodman’s Free-Fall Metal Detectors are expertly designed to meet stringent international food safety standards, achieving full compliance with IFS, BRC, and FSMA requirements. By aligning with these global guidelines, the detectors enhance food safety protocols and ensure consistent quality control throughout production.

Adaptable Application

Ideal for inspecting a range of granular products like milk powder, sugar, corn, tea, noodles, and crisps, this detector supports versatile applications in food processing.

Reliable Build Quality

Designed to endure tough industrial settings, this detector offers durability and long-lasting performance for continuous operations.

What Makes FOODMAN X-RAY INSPECTION SYSTEM DIFFERENT?

AI Based Technology