Introduction

X-ray inspection system offers a revolutionary approach by utilizing advanced imaging to detect foreign objects based on density differences. Unlike traditional methods, it can identify a broad range of contaminants, including non-metallic impurities, ensuring higher accuracy and safety standards.

What Is X-Ray Inspection Technology?

Definition and Basic Principles

X-ray inspection technology is a non-invasive, non-destructive imaging technique that uses X-rays to penetrate materials and create detailed images. By capturing density variations within a product, it identifies foreign objects that differ in density from the main product.

How X-Rays Work

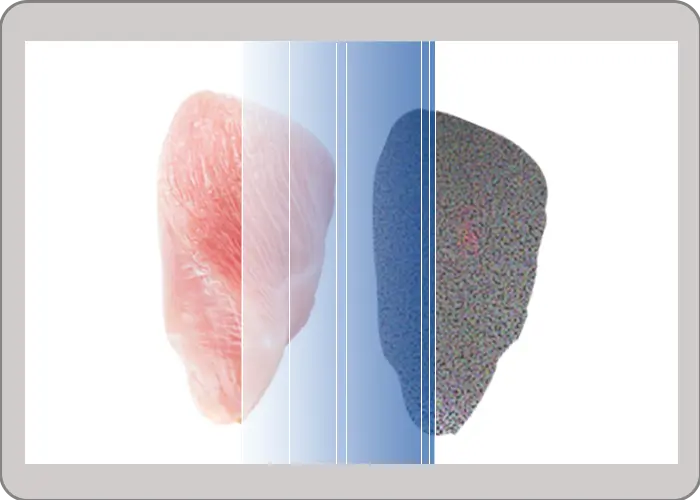

When X-rays pass through an object, denser materials absorb more radiation and appear brighter on the resulting image. This contrast allows the system to identify foreign objects, regardless of whether they are metallic or non-metallic.

Comparison with Other Inspection Technologies

Compared to metal detectors, X-ray systems excel in detecting a wider range of contaminants, including glass, stones, and rubber. Unlike visual inspections, X-ray technology ensures consistent accuracy by eliminating human error and detecting impurities invisible to the naked eye.

Key Components of an X-Ray Inspection System

X-Ray Generator

The X-ray generator produces the X-rays necessary for inspection. Its quality and power determine the system’s penetration ability and overall performance. High-power generators can effectively inspect dense or multi-layered products.

Detectors

Detectors capture X-rays that pass through the product and convert them into digital signals. Advanced detectors offer high resolution, ensuring that even the smallest foreign objects are identified accurately.

Software and Algorithms

The software processes the captured data, using algorithms to analyze the image for foreign objects. Modern systems incorporate AI algorithms, which improve detection accuracy by learning to distinguish between the product and potential contaminants.

User Interface

A user-friendly interface enables operators to monitor inspection results in real time, adjust settings, and analyze data effectively. This simplifies the decision-making process and ensures seamless operation.

How X-Ray Detects Foreign Objects

Density-Based Detection

X-ray systems rely on density-based detection, which identifies foreign objects that differ in density from the product. For example, glass or stones, which are denser than most food products, appear prominently in X-ray images.

Types of Detectable Foreign Objects

X-ray inspection systems can detect a wide range of contaminants, including:

Metal: Ferrous (Fe), non-ferrous (non-Fe), and stainless steel.

Glass, Stones, and Ceramics: Commonly found in food and beverage production environments.

Plastics and Rubber: Often used in production machinery and packaging.

Bone Fragments and Shells: Particularly relevant in meat and seafood processing.

X-ray Systems and Their Ability to Analyze Material Composition

Advanced X-ray systems, such as those equipped with dual-energy technology, take detection a step further by analyzing the composition of materials. Dual-energy X-ray systems capture images at two different energy levels, enabling them to differentiate between materials of similar density but different atomic structures.

Industries That Benefit from X-Ray Inspection

Food Industry

In the food industry, X-ray inspection system ensures consumer safety by detecting contaminants in packaged products. From stones in grains to bones in meat, X-ray technology addresses a variety of challenges.

Pharmaceuticals

X-ray machine plays a critical role in pharmaceuticals by identifying foreign objects in tablets, capsules, and powders. This ensures product efficacy and prevents health risks.

Cosmetics and Personal Care

For cosmetics, X-ray inspection detects foreign objects in creams, lotions, powders, and other products, maintaining premium quality standards.

Beverage Industry

X-ray systems inspect glass bottles for shards or contaminants, providing reliable quality assurance for liquid products and safeguarding consumers from potential injuries.

Benefits of Using X-Ray Inspection Systems

Improved Detection Accuracy

X-ray inspection systems are highly accurate, capable of detecting even low-density impurities that traditional methods cannot.

Reduced Product Recalls and Waste

By identifying contaminants early in the production process, manufacturers can minimize product recalls, reduce waste, and save costs.

Compliance with Safety Standards

X-ray inspection machines ensure compliance with international safety regulations, such as HACCP, BRC, and FDA standards, making them indispensable for global markets.

Enhanced Brand Reputation

Delivering safe and high-quality products enhances consumer trust, strengthens brand loyalty, and protects the company’ s reputation.

Conclusion

Recap of X-Ray Inspection’ s Importance

X-ray inspection technology is transforming foreign object detection by providing unmatched accuracy and versatility. Its ability to detect a broad range of contaminants ensures safety, quality, and regulatory compliance.

Why Invest in X-Ray Technology

Investing in X-ray systems enhances quality control, reduces operational risks, and builds long-term consumer trust. For manufacturers, it’ s a vital tool for maintaining competitive advantage in a demanding marketplace.

Call to Action

Elevate your quality assurance processes with Foodman’ s advanced X-Ray Inspection Systems. Contact us today to discover how our innovative solutions can help you achieve superior safety and quality standards.