This system is suitable for detecting foreign metal objects in bulk products, including powders, granules, and other loose materials.

Introduction to Bulk Industry Challenges

Inconsistent Product Density

Bulk products, such as grains, nuts, or powders, can vary in density as they move along the conveyor. This inconsistency makes it difficult to detect smaller contaminants. Advanced X-ray systems with adaptable sensitivity can adjust to varying product densities, ensuring reliable detection even in loosely packed or uneven product flows.

High Speed of Bulk Flow

Bulk products often pass through the inspection system at high speeds, which can challenge the system’s accuracy. High-speed X-ray inspection systems with real-time image processing maintain consistent detection performance, enabling thorough inspections without slowing down production.

Hard-to-Detect Contaminants

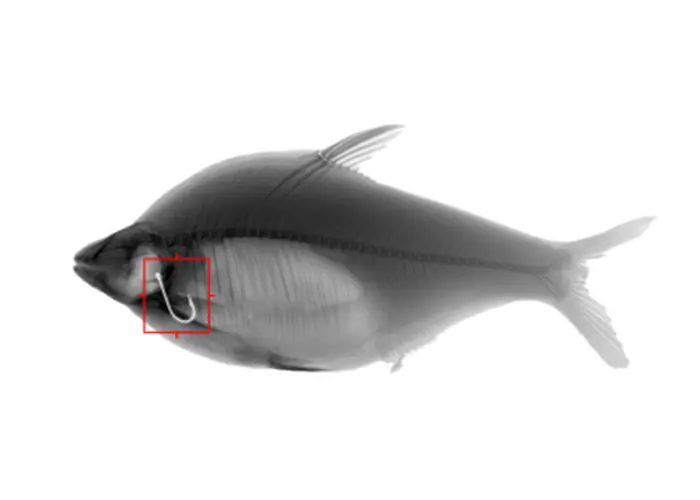

Tiny foreign objects like stones or glass fragments can be difficult to spot within bulk products. High-resolution X-ray systems with enhanced contrast settings and dual-energy technology help identify even minute contaminants, ensuring product safety.

Product Overlap and Clumping

Bulk products can overlap or clump together on the conveyor, hiding contaminants within thicker product layers. Specialized X-ray algorithms can penetrate these layers, analyzing overlapping or clumped items to ensure complete inspection coverage.

Adaptation to Various Bulk Product Types

X-ray inspection needs can vary widely based on the type of bulk product—fine powders, grains, or irregularly shaped nuts. Advanced X-ray systems allow for customizable inspection parameters, allowing them to be adjusted to different bulk product characteristics for effective inspection across multiple product types.

Preventing False Positives in Natural Products

Bulk items like nuts or grains can have natural irregularities that sometimes mimic contaminants, causing false positives. X-ray inspection systems with intelligent algorithms are trained to distinguish between harmless product variations and actual contaminants, reducing false reject rates and improving overall efficiency.

Core Technologies of Bulk X-Ray Inspection Systems

FDX

Foodman employs FDX technology, which integrates industry-leading dual-energy TDI high-resolution detectors with advanced dual-energy image analysis algorithms and deep learning techniques. This combination enables Foodman systems to perform precise material analysis, identify low-density impurities, and detect morphological features with exceptional accuracy. By utilizing FDX technology, Foodman enhances the detection capabilities of its X-ray inspection systems, ensuring higher efficiency, reliability, and safety in food processing and packaging.

FIAP

Foodman utilizes FIAP, which leverages advanced AI algorithms and deep learning techniques to enhance detection performance. By analyzing a vast amount of image data, FIAP significantly improves processing speed and detection accuracy. This technology ensures that Foodman’ s X-ray inspection systems can detect even the most subtle irregularities in food products, providing faster, more reliable results while maintaining the highest standards of quality and safety in food production.。

AI

Foodman incorporates advanced AI technology into its systems to optimize detection and quality control. By utilizing AI algorithms, Foodman’ s X-ray inspection systems can analyze vast amounts of data quickly and accurately. The AI-driven approach enhances the system’s ability to identify even the smallest contaminants or irregularities in food products, improving detection precision and operational efficiency. This integration of AI ensures consistent, high-quality results while reducing human error, making Foodman a trusted solution for food safety and quality assurance.

Choose the Right Detect Machine for Your Bulk Line

Overview of different Foodman X-ray machines suitable for various bulk types

Free Fall Metal Detector FMD-P-80

Suitable for detecting foreign metal objects in bulk products such as powers and granules.

X-Ray Inspection System For Medium Unpackaged Bulk Products

This machine is suitable for loose and unpackaged materials such as nuts, oatmeal, wheat, rice and other grains, candies, capsules, tablets, rubber particles, etc.

X-Ray Inspection System For Large Unpackaged Bulk Products FXR-S6035

This machine is ideal for loose, unpackaged items like nuts, oatmeal, wheat, rice, various grains, candies, capsules, tablets, and rubber particles.

Foodman Amazing Clients