The machine is highly effective for inspecting poultry and meat products, including chicken, pork, beef, and other processed meats. It is capable of detecting various foreign objects and contaminants.

Introduction to Meat Poultry Industry Challenges

Variable Density in Meat Cuts

Meat and poultry products vary significantly in density due to bone, muscle, and fat content, which can complicate contamination detection. Advanced X-ray inspection systems with adaptable density detection calibrate settings to accommodate these differences, ensuring accurate results for various meat cuts.

Detection of Small Bones and Foreign Materials

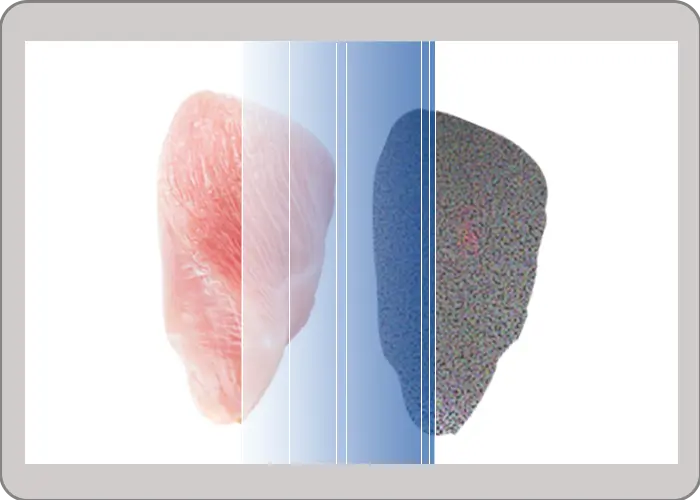

Tiny bones, like those in poultry, are often difficult to detect within the product. X-ray systems equipped with high-resolution sensors and dual-energy technology can differentiate bone fragments from other structures, enhancing detection accuracy even for small or embedded bones.

Packaging Interference

Meat and poultry are often wrapped in various materials, including aluminum foil, which can interfere with standard detection methods. X-ray inspection systems designed to penetrate specific packaging materials are calibrated to reduce interference, ensuring contaminants are identified regardless of packaging type.

Moisture and Temperature Variations

Meat products have high moisture content and are often processed in cold environments, which can affect the performance of detection systems. X-ray systems with robust cooling mechanisms and moisture-resistant components operate effectively in chilled or humid conditions, maintaining stable inspection results.

Preventing False Positives Due to Tissue Variability

Irregular shapes and textures in meat and poultry can mimic foreign objects, leading to false positives. Intelligent algorithms in X-ray systems can distinguish between normal product variations and actual contaminants, minimizing false rejects and increasing processing efficiency.

High-Speed Processing Requirements

Meat and poultry production lines often operate at high speeds, which can strain detection accuracy. High-speed X-ray inspection systems with real-time image processing can keep up with production demands without compromising on contamination detection, ensuring each product is thoroughly inspected.

Core Technologies of Meat Poultry X-Ray Inspection Systems

FDX

Foodman employs FDX technology, which integrates industry-leading dual-energy TDI high-resolution detectors with advanced dual-energy image analysis algorithms and deep learning techniques. This combination enables Foodman systems to perform precise material analysis, identify low-density impurities, and detect morphological features with exceptional accuracy. By utilizing FDX technology, Foodman enhances the detection capabilities of its X-ray inspection systems, ensuring higher efficiency, reliability, and safety in food processing and packaging.

FIAP

Foodman utilizes FIAP, which leverages advanced AI algorithms and deep learning techniques to enhance detection performance. By analyzing a vast amount of image data, FIAP significantly improves processing speed and detection accuracy. This technology ensures that Foodman’ s X-ray inspection systems can detect even the most subtle irregularities in food products, providing faster, more reliable results while maintaining the highest standards of quality and safety in food production.。

AI

Foodman incorporates advanced AI technology into its systems to optimize detection and quality control. By utilizing AI algorithms, Foodman’ s X-ray inspection systems can analyze vast amounts of data quickly and accurately. The AI-driven approach enhances the system’s ability to identify even the smallest contaminants or irregularities in food products, improving detection precision and operational efficiency. This integration of AI ensures consistent, high-quality results while reducing human error, making Foodman a trusted solution for food safety and quality assurance.

Choose the Right Detect Machine for Your Meat Poultry Line

Overview of different Foodman X-ray machines suitable for various meat poultry types

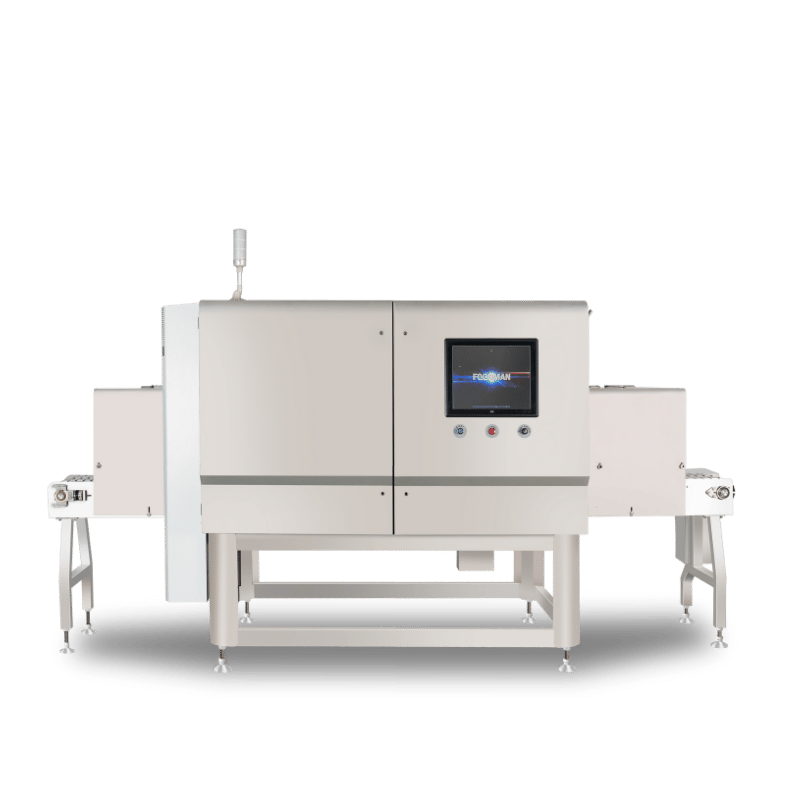

Dual Beam Side Scan X-Ray Inspection System FXR-C180-2

It can be applied in the detection of meat and poultry, such as chicken, pork, and beef.

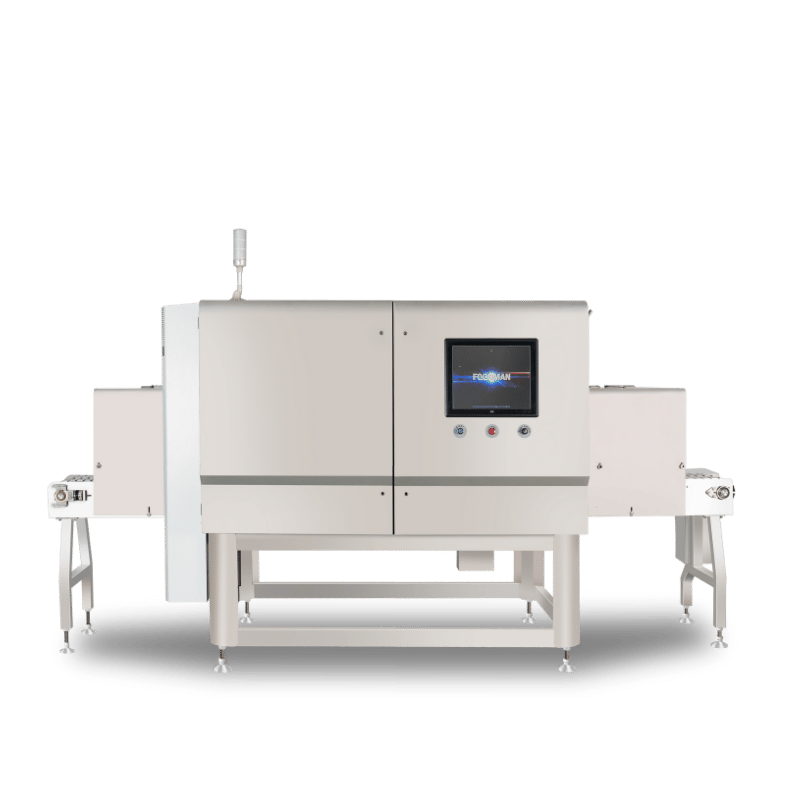

Dual Energy X-Ray Inspection System For Tiny Bones

The machine is effective for the inspection of poultry and meat products, including chicken, pork, and beef.

Dual Energy X-Ray Inspection System For Large Bones

It is suitable for detecting meat and poultry products, including chicken, pork, and beef.

X-Ray Inspection System For Packaged Products

This system can be used to inspect meat and poultry, such as chicken, pork, and beef.

Dual Beam Side Scan X-Ray Inspection System FXR-C180-2

It can be applied in the detection of meat and poultry, such as chicken, pork, and beef.

Dual Energy X-Ray Inspection System For Tiny Bones

The machine is effective for the inspection of poultry and meat products, including chicken, pork, and beef.

Foodman Amazing Clients