Ensure the highest standards of safety and quality for your cheese and dairy products with our advanced X-ray inspection system. Designed specifically for the dairy industry, this progressive technology detects foreign bodies like glass, metal, and dense plastics while also identifying missing, broken, or deformed products.

Introduction to Snack Industry Challenges

Detecting Foreign Contaminants

Ensuring the identification of contaminants such as metal, glass, plastic, or stones is challenging due to the diversity of dairy product types and packaging. Low-density contaminants, like rubber or organic materials, are particularly hard to detect.

Product and Packaging Variability

Cheese and dairy products come in many forms—liquid, solid, grated, or slices—and use various packaging materials such as vacuum packs or cartons. Inspection systems must adapt to these variations without compromising accuracy.

Regulatory Compliance

The dairy industry must meet strict global safety standards, such as FDA, HACCP, and BRC. Adhering to these regulations while keeping up with production demands requires advanced inspection technologies and robust quality assurance processes.

False Rejection Issues

Highly sensitive inspection systems often produce false rejects, discarding products that meet quality standards. This increases waste and operational costs while slowing production.

High-Speed Production Challenges

Modern dairy production lines operate at high speeds, requiring inspection systems to perform with precision and efficiency to avoid bottlenecks or undetected contaminants.

Moisture and Texture Consistency

Maintaining consistent moisture levels and textures in soft cheeses or processed dairy products is critical. Variability in production processes or environmental factors can impact product quality and shelf life.

Core Technologies of Snack X-Ray Inspection Systems

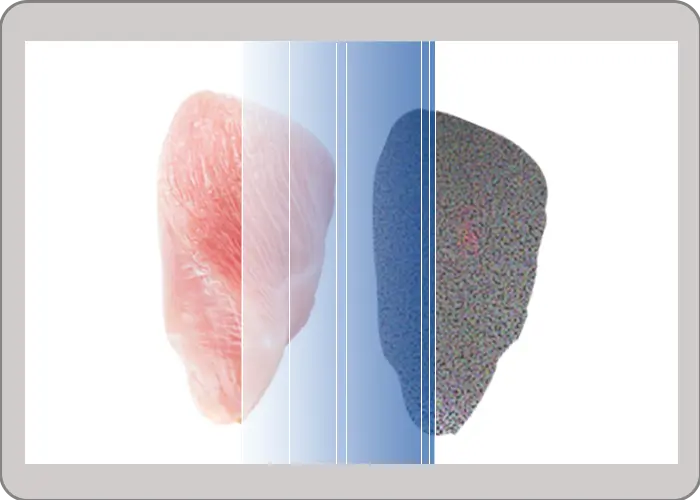

FDX

Foodman employs FDX technology, which integrates industry-leading dual-energy TDI high-resolution detectors with advanced dual-energy image analysis algorithms and deep learning techniques. This combination enables Foodman systems to perform precise material analysis, identify low-density impurities, and detect morphological features with exceptional accuracy. By utilizing FDX technology, Foodman enhances the detection capabilities of its X-ray inspection systems, ensuring higher efficiency, reliability, and safety in food processing and packaging.

FIAP

Foodman utilizes FIAP, which leverages advanced AI algorithms and deep learning techniques to enhance detection performance. By analyzing a vast amount of image data, FIAP significantly improves processing speed and detection accuracy. This technology ensures that Foodman’ s X-ray inspection systems can detect even the most subtle irregularities in food products, providing faster, more reliable results while maintaining the highest standards of quality and safety in food production.。

AI

Foodman incorporates advanced AI technology into its systems to optimize detection and quality control. By utilizing AI algorithms, Foodman’ s X-ray inspection systems can analyze vast amounts of data quickly and accurately. The AI-driven approach enhances the system’s ability to identify even the smallest contaminants or irregularities in food products, improving detection precision and operational efficiency. This integration of AI ensures consistent, high-quality results while reducing human error, making Foodman a trusted solution for food safety and quality assurance.

Choose the Right Detect Machine for Your Snack Line

Overview of different Foodman X-ray machines suitable for various snack types

X-Ray Inspection System For Small Sachets

This X-ray machine is suitable for inspecting cheese and dairy.

X-Ray Inspection System For Packaged Products

This X-ray machine works perfectly with items such as cheese and dairy.

Single Beam Side Scan X-Ray Inspection System FXR-C180

This machine is specially designed to detect cheese and dairy.

Dual Beam Side Scan X-Ray Inspection System FXR-C180-2

This X-ray machine is ideal for inspecting cheese and dairy.

Foodman Amazing Clients